Reach Stacker Telescopic Cylinder

As one of the telescopic cylinder manufacturers, suppliers, and exporters of mechanical products, We offer telescopic cylinders and many other products.

Please get in touch with us for details.

Telescopic Cylinders

A reach stacker telescopic cylinder is a hydraulic cylinder that is used to extend and retract the reach of a reach stacker. Reach stackers are used to load and unload containers from ships, trains, and trucks and to stack containers in storage yards. Telescopic cylinders work by having multiple sections that can slide inside of each other. When hydraulic fluid is pumped into the cylinder, the sections extend. When the hydraulic fluid is drained, the sections retract.

Reach stacker telescopic cylinders are typically double-acting, meaning that they can extend and retract using the same hydraulic circuit. This allows for more precise control of the reach of the reach stacker. Reach stacker telescopic cylinders are made from high-strength steel and are designed to withstand the rigors of heavy-duty industrial use. They are also equipped with seals and bearings to protect them from wear and tear.

Reach stacker telescopic cylinders are an essential component of reach stackers, and they play a vital role in the efficient handling of containers. Here are some of the key benefits of using reach stacker telescopic cylinders:

- Increased reach: Telescopic cylinders allow reach stackers to reach further, which can improve efficiency and productivity.

- Improved maneuverability: Telescopic cylinders can help reach stackers to maneuver more easily in tight spaces.

- Reduced wear and tear: Telescopic cylinders can help to reduce wear and tear on other components of the reach stacker, such as the mast and forks.

- Increased safety: Telescopic cylinders can help to improve safety by providing more control over the reach of the reach stacker.

Reach stacker telescopic cylinders are an essential component of reach stackers, and they play a vital role in the efficient and safe handling of containers.

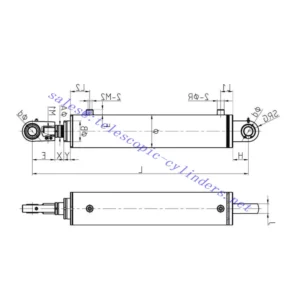

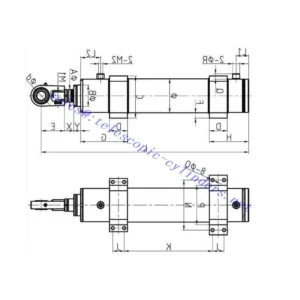

Reach Stacker Telescopic Cylinder Specifications:

| Product Name | Reach Stacker Telescopic Cylinder |

| Features: | Realize the linear telescopic movement of the boom |

| Bore diameter: | 200mm~220mm |

| Rod diameter: | 150mm~180mm Stroke≤8000mm |

| Pressure: | Maximum 30MPa |

| Applications: | Reach Stacker |

Benefits of Using the Reach Stacker Telescopic Cylinder:

The reach stacker telescopic cylinder is a key component of the reach stacker, allowing it to extend and retract its boom to reach and stack containers of different heights. Telescopic cylinders offer a number of benefits for reach stackers, including:

1. Increased reach and flexibility: Telescopic cylinders allow the reach stacker to reach containers that are further away and to stack containers in different configurations. This makes reach stackers more versatile and efficient for a variety of container-handling applications.

2. Improved safety: Telescopic cylinders help to reduce the risk of accidents by providing a more stable and controlled lifting and stacking operation.

3. Reduced wear and tear: Telescopic cylinders are designed to minimize wear and tear on the reach stacker, resulting in lower maintenance costs and longer equipment lifespan.

4. Improved fuel efficiency: Telescopic cylinders help to improve the fuel efficiency of the reach stacker by reducing the amount of time and energy required to lift and stack containers.

In addition to these general benefits, telescopic cylinders can also offer specific advantages for reach stackers in certain applications. For example, reach stackers with telescopic cylinders can be used to stack containers in more confined spaces, such as those found in railway yards or inland ports. Telescopic cylinders can also be used to stack containers on uneven surfaces, such as those found in container depots or on barges.

Overall, the reach stacker telescopic cylinder is a versatile and reliable component that offers a number of benefits for reach stackers. By increasing reach and flexibility, improving safety, reducing wear and tear, and improving fuel efficiency, telescopic cylinders help reach stackers to operate more efficiently and cost-effectively.

The Role of Reach Stacker Telescopic Cylinder:

Here are some specific examples of how the reach stacker telescopic cylinder can be beneficial in different applications:

(1) Stacking containers in multiple rows: Telescopic cylinders allow reach stackers to stack containers in multiple rows, even when there is limited space between the rows. This can help to increase storage capacity and efficiency in container terminals.

(2) Stacking containers on uneven surfaces: Telescopic cylinders allow reach stackers to stack containers on uneven surfaces, such as those found in container depots or on barges. This can be helpful for loading and unloading containers from ships and trains.

(3) Stacking containers in confined spaces: Telescopic cylinders allow reach stackers to stack containers in confined spaces, such as those found in railway yards or inland ports. This can be helpful for loading and unloading containers from trains and trucks.

Overall, the reach stacker telescopic cylinder is a valuable tool that can help reach stackers to perform a variety of tasks more efficiently and safely.

China Reach Stacker Cylinder Manufacturers

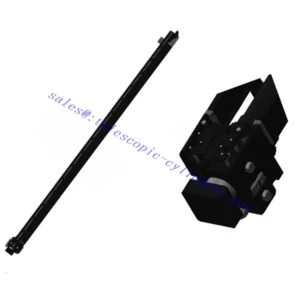

The reach stacker is a kind of crane used to load and unload containers. The number of stacking layers and the utilization rate of the yard are the most important indicators to test its performance. In fact, it puts forward higher requirements on the load-lifting capacity of the spreader. At the same time, it is requested to be easy to operate and shuttle between channels flexibly. The lifting cylinders and telescopic cylinders designed and produced by HZPT adopt a special structural design with the characteristics of corrosion resistance, wear resistance, and long life and could meet the high requirements of reach stackers and high-frequency load lifting operation conditions.

Moreover, we go beyond reach stacker cylinders. We also supply a diverse range of hydraulic cylinders, including industrial vehicle hydraulic cylinders, aerial work vehicle cylinders, mobile machinery cylinders, industrial engineering cylinders, construction machinery cylinders, forklift hydraulic cylinders, agricultural machinery cylinders, crane hydraulic cylinders, sanitation machinery cylinders, excavator hydraulic cylinders, offshore hydraulic cylinders, energy technology cylinders, tunnel boring machine cylinders, and more. Our extensive product lineup caters to various industries and applications, providing solutions for your hydraulic needs.

We are one of the best telescopic cylinder manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair's adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair's base and connects to the seat or the chair's mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair's remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Application

Factory tour