Aerial Work Platform Telescopic Cylinder

As one of the telescopic cylinder manufacturers, suppliers, and exporters of mechanical products, We offer telescopic cylinders and many other products.

Please get in touch with us for details.

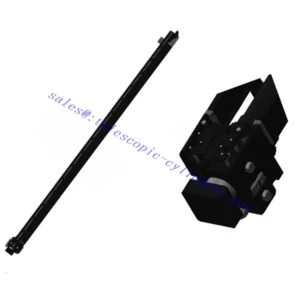

Telescopic Cylinders

An aerial work platform telescopic cylinder is a hydraulic cylinder that is used to extend and retract the boom of an aerial work platform. It is a critical component of the platform, as it allows the platform to reach its full height and provide access to elevated areas.

Telescopic cylinders are made up of a series of telescoping tubes that are connected by pistons. When the cylinder is extended, the pistons push the tubes out, causing the cylinder to lengthen. When the cylinder is retracted, the pistons pull the tubes in, causing the cylinder to shorten.

Aerial work platform telescopic cylinders are typically made of high-strength steel and are designed to withstand the weight of the platform and its occupants. They are also designed to be durable and reliable, as they are subjected to a lot of wear and tear.

The size and capacity of an aerial work platform telescopic cylinder will vary depending on the size and capacity of the platform. Smaller platforms will typically have smaller cylinders, while larger platforms will typically have larger cylinders.

The performance of an aerial work platform telescopic cylinder is affected by a number of factors, including the quality of the materials used, the design of the cylinder, and the maintenance of the cylinder.

Well-maintained aerial work platform telescopic cylinders can last for many years. However, if they are not properly maintained, they can wear out prematurely and fail.

Here are some of the benefits of using an aerial work platform telescopic cylinder:

- They allow the platform to reach its full height, providing access to elevated areas.

- They are durable and reliable, making them a long-lasting investment.

- They are easy to maintain, requiring only basic lubrication and inspection.

Aerial work platform telescopic cylinders are an essential component of aerial work platforms. They allow the platforms to reach their full height and provide access to elevated areas, making them a valuable tool for a variety of applications.

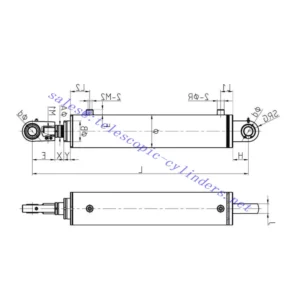

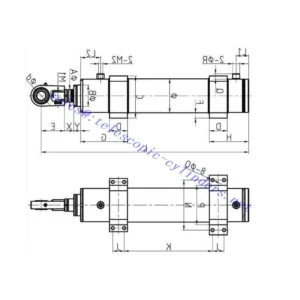

Aerial Work Platform Telescopic Cylinder Specifications:

| Product Name | Aerial Work Platform Telescopic Cylinder |

| Features: | Realize the linear telescopic movement of the boom |

| Bore diameter: | 45mm~200mm |

| Rod diameter: | 32mm~180mm Stroke≤15000mm |

| Pressure: | 30MPa(Maximum pressure |

| Telescopic Cylinder Applications: | Aerial Work Platform |

Aerial Work Platform Telescopic Cylinder Advantages:

Telescopic cylinders are commonly used in aerial work platforms (AWPs) to provide the necessary lifting and extension capabilities. These cylinders offer several advantages that make them suitable for aerial work platform applications. Here are some key advantages of telescopic cylinders in aerial work platforms:

1. Increased Reach: Telescopic cylinders allow aerial work platforms to achieve greater heights and extended reach compared to other types of lifting mechanisms. The telescopic design enables multiple stages or sections to extend and retract, providing incremental height adjustments as needed. This feature is particularly beneficial in industries such as construction, maintenance, and utilities where access to elevated areas is required.

2. Compact Design: Aerial work platform telescopic cylinders offer a compact and space-saving design. The nested sections allow the cylinder to collapse into a smaller overall length when retracted, making it easier to transport and store aerial work platforms. This compactness is especially advantageous for mobile or truck-mounted platforms where space is limited.

3. Versatility: Aerial work platform telescopic cylinders can be used in various applications and environments. The adjustable height feature allows for flexible positioning, enabling operators to reach specific areas with precision. Telescopic cylinders also provide horizontal outreach, allowing workers to access areas that are not directly beneath the platform, such as over obstacles or structures.

4. Smooth Operation: Aerial work platform telescopic cylinders provide smooth and controlled movement during extension and retraction. The individual stages of the cylinder slide within one another, reducing the jerky motion that can occur with other lifting mechanisms. This smooth operation enhances operator comfort, improves safety, and allows for more precise positioning of the platform.

5. High Load Capacity: Aerial work platform telescopic cylinders are designed to handle heavy loads, making them suitable for aerial work platform applications that require lifting personnel, tools, and equipment to elevated heights. The nested sections of the cylinder provide structural support and distribute the load evenly, ensuring stability and safety during operation.

6. Reliability and Durability: Aerial work platform telescopic cylinders are constructed with robust materials and components that are designed to withstand the demanding conditions of aerial work platform operations. They are engineered to provide long-lasting performance, requiring minimal maintenance over their operational lifespan. This reliability ensures that aerial work platforms equipped with telescopic cylinders can be used consistently and efficiently.

Telescopic Hydraulic Cylinder for Aerial Work Platform:

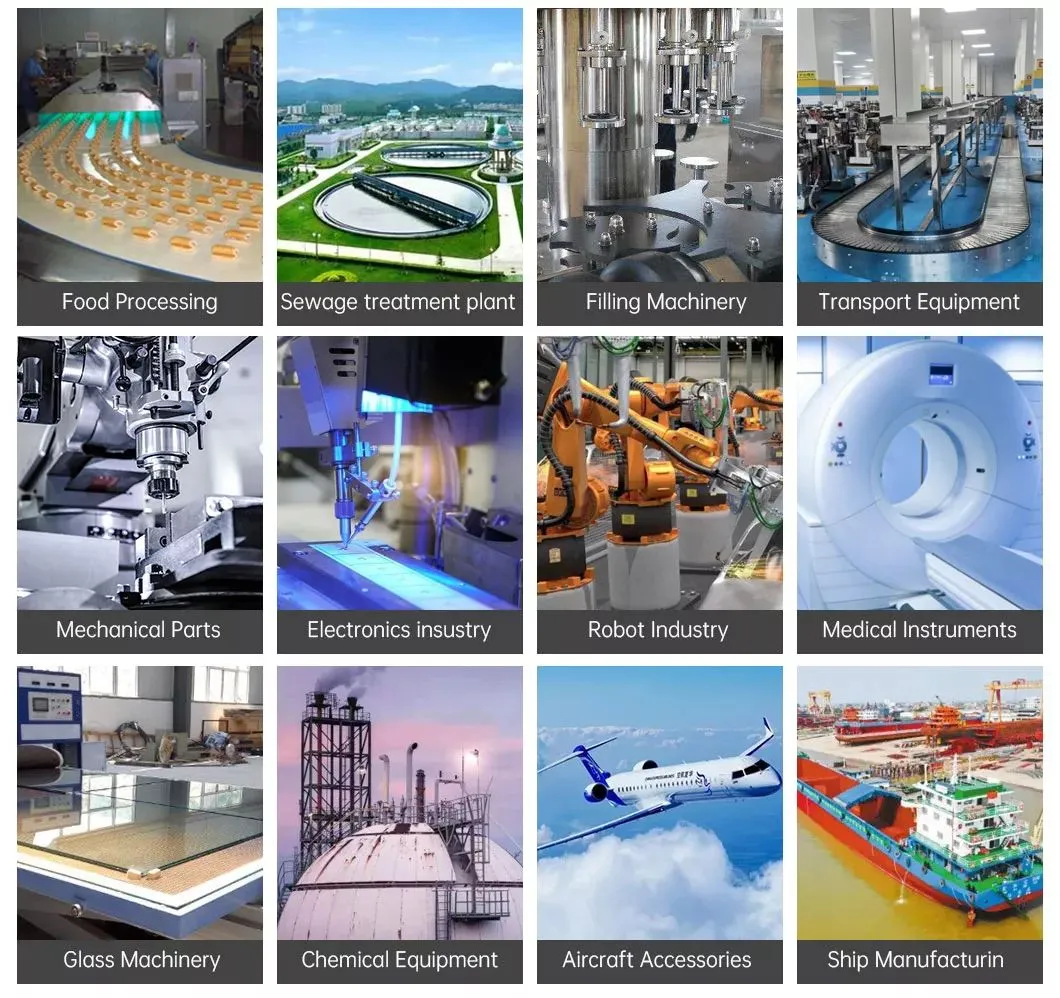

Telescopic hydraulic cylinders find numerous applications in aerial work platforms (AWPs) due to their ability to provide vertical and horizontal extension capabilities. Here are some common applications of telescopic hydraulic cylinders in aerial work platforms:

(1) Construction and Maintenance: Telescopic hydraulic cylinders are extensively used in construction and maintenance applications where workers need to access elevated areas. They are employed in boom lifts, scissor lifts, and cherry pickers to provide the necessary height and reach for tasks such as building construction, exterior maintenance, painting, window cleaning, and equipment installation.

(2) Utilities and Infrastructure: Aerial work platform telescopic cylinders are widely utilized in the utilities and infrastructure sectors. They allow workers to reach overhead power lines, streetlights, telecommunications equipment, bridges, and other infrastructure elements for inspection, repair, and maintenance purposes.

(3) Warehousing and Inventory Management: Telescopic hydraulic cylinders are employed in aerial work platforms used in warehousing and inventory management operations. These platforms enable workers to access high shelves or racks for stock picking, storage, and retrieval. The telescopic cylinder's reach and height adjustment capabilities facilitate efficient inventory management and optimize storage space utilization.

(4) Emergency Services: Aerial work platform telescopic cylinders play a crucial role in emergency services such as firefighting, rescue operations, and disaster response. They enable personnel to reach heights quickly and safely for extinguishing fires, performing rescues, conducting search and rescue operations, and providing access to elevated areas during emergencies.

(5) Event Management: Telescopic hydraulic cylinders are commonly used in event management for setting up stages, lighting rigs, sound systems, and decorations. They allow event organizers to reach high ceilings, rigging points, or outdoor structures for installation, adjustment, and dismantling purposes.

(6) Agricultural and Horticultural Applications: In the agricultural and horticultural sectors, aerial work platform telescopic cylinders assist in tasks such as fruit picking, pruning, and maintenance of tall trees, as well as greenhouse operations. These platforms provide elevated work areas, improving efficiency and reducing the risk of injury.

China Aerial Work Platform Cylinder Manufacturers

In 30 years of focusing on innovation, HZPT has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile, HZPT is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Hangzhou, HZPT has founded five hydraulic R&D centers in China, Germany, the United States, Japan, and Mexico, and ten manufacturing bases worldwide. HZPT the establishment of a high-precision foundry and a pump & valve factory, HZPT has mastered the key to developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields such as mobile machinery, agricultural machinery, industrial engineering, offshore, energy technology, and tunnel boring machines.

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce industrial vehicle hydraulic cylinders, aerial work vehicle hydraulic cylinders, small excavator bucket cylinders, construction machinery hydraulic cylinders, forklift hydraulic cylinders, crane luffing hydraulic cylinders and sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

HZPT is committed to providing customers with efficient hydraulic technology solutions and products, maintaining strong partnerships with customers, and leading the development of China’s hydraulic industry through more scientific solutions. HZPT aims to make more contributions to the sustainable development of society, the construction of green cities, and building a better future.

We are one of the best telescopic cylinder manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair's adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair's base and connects to the seat or the chair's mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair's remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Application

Factory tour