Mobile Crane Telescopic Cylinder

As one of the telescopic cylinder manufacturers, suppliers, and exporters of mechanical products, We offer telescopic cylinders and many other products.

Please get in touch with us for details.

Telescopic Cylinders

A mobile crane telescopic cylinder is a hydraulic cylinder that is used to extend and retract the boom of a mobile crane. It is a critical component of the crane, as it allows the crane to reach greater heights and lift heavier loads.

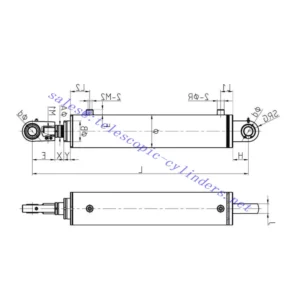

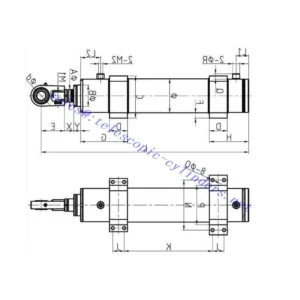

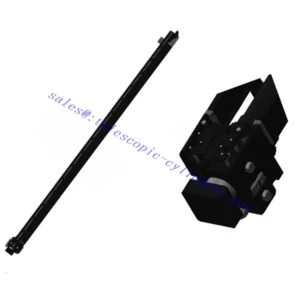

Mobile crane telescopic cylinders are made up of a series of nested tubes that slide inside each other. When the cylinder is extended, the tubes slide out, increasing the length of the cylinder. When the cylinder is retracted, the tubes slide back in, decreasing the length of the cylinder.

There are two main types of telescopic cylinders: single-acting and double-acting. Single-acting telescopic cylinders are only powered by one hydraulic fluid circuit, which is used to extend the cylinder. Double-acting telescopic cylinders are powered by two hydraulic fluid circuits, one for extending the cylinder and one for retracting it.

Mobile crane telescopic cylinders are typically made of high-strength steel and are designed to withstand the high pressures and loads that are encountered during operation. They are also equipped with safety features, such as pressure relief valves, to prevent them from overextending or overloading.

Mobile crane telescopic cylinders are a vital part of mobile cranes and are essential for their safe and efficient operation. They are used in a wide variety of applications, including construction, demolition, and lifting.

Mobile Crane Telescopic Cylinder Specifications:

| Product Name | Mobile Crane Telescopic Cylinder |

| Features: | Realize the linear telescopic movement of the boom |

| Bore diameter: | 75mm~360mm |

| Rod diameter: | 50mm~320mm Stroke≤22000mm |

| Pressure: | Maximum 42MPa |

| Hydraulic Steering Cylinder Applications: | Mobile Crane |

Benefits of Mobile Crane Telescopic Cylinder:

The mobile crane telescopic cylinder is a key component of a mobile crane. It is responsible for extending and retracting the boom, which allows the crane to reach different heights and distances. Telescopic cylinders offer a number of benefits over other types of cylinders, including:

1. Variable Reach and Height: The mobile crane telescopic cylinder allows for the extension and retraction of the crane's boom sections, providing variable reach and height capabilities. This flexibility enables the crane to adapt to different job site requirements and lift loads at various distances and elevations.

2. Increased Lifting Capacity: By extending the boom sections, the mobile crane telescopic cylinder allows the crane to achieve greater lifting capacities. The nested design of the cylinder ensures stability and strength while extending the boom, enabling the crane to handle heavier loads with precision.

3. Compact Design: The mobile crane telescopic cylinder's nested sections can be retracted, resulting in a more compact and maneuverable crane configuration during transportation and storage. This compact design is particularly advantageous when navigating confined spaces or transporting the crane to different job sites.

4. Efficient Operation: The hydraulic-powered mobile crane telescopic cylinder offers smooth and controlled extension and retraction of the boom sections. This allows for precise positioning and efficient operation, reducing the time required for setup and maximizing productivity on the job site.

5. Safety Features: The mobile crane telescopic cylinder is equipped with safety features such as hydraulic locks or latches that secure the boom sections in place during lifting operations. These features prevent unintended movement, ensuring the stability and safety of the crane during lifting activities.

6. Versatility: Mobile crane telescopic cylinders are versatile machines suitable for a wide range of applications. They can be used in construction sites, industrial settings, shipping yards, and more. The ability to adjust the boom length and reach makes them adaptable to different job requirements, enhancing their versatility.

China Mobile Crane Cylinder Manufacturers

In 30 years of focusing on innovation, HZPT has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile, HZPT is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Hangzhou, HZPT has founded five hydraulic R&D centers in China, Germany, the United States, Japan, and Mexico, and ten manufacturing bases worldwide. HZPT the establishment of a high-precision foundry and a pump & valve factory, HZPT has mastered the key to developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields such as mobile machinery, agricultural machinery, industrial engineering, offshore, energy technology, and tunnel boring machines.

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce industrial vehicle hydraulic cylinders, aerial work vehicle hydraulic cylinders, small excavator bucket cylinders, construction machinery hydraulic cylinders, forklift hydraulic steering cylinders, crane luffing hydraulic cylinders, and sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

HZPT is committed to providing customers with efficient hydraulic technology solutions and products, maintaining strong partnerships with customers, and leading the development of China’s hydraulic industry through more scientific solutions. HZPT aims to make more contributions to the sustainable development of society, the construction of green cities, and building a better future.

We are one of the best telescopic cylinder manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair's adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair's base and connects to the seat or the chair's mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair's remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Application

Factory tour