Oil/Gas Drilling Platform Derrick Lifting Cylinder

As one of the telescopic cylinder manufacturers, suppliers, and exporters of mechanical products, We offer telescopic cylinders and many other products.

Please get in touch with us for details.

Energy Technology Hydraulic Cylinders

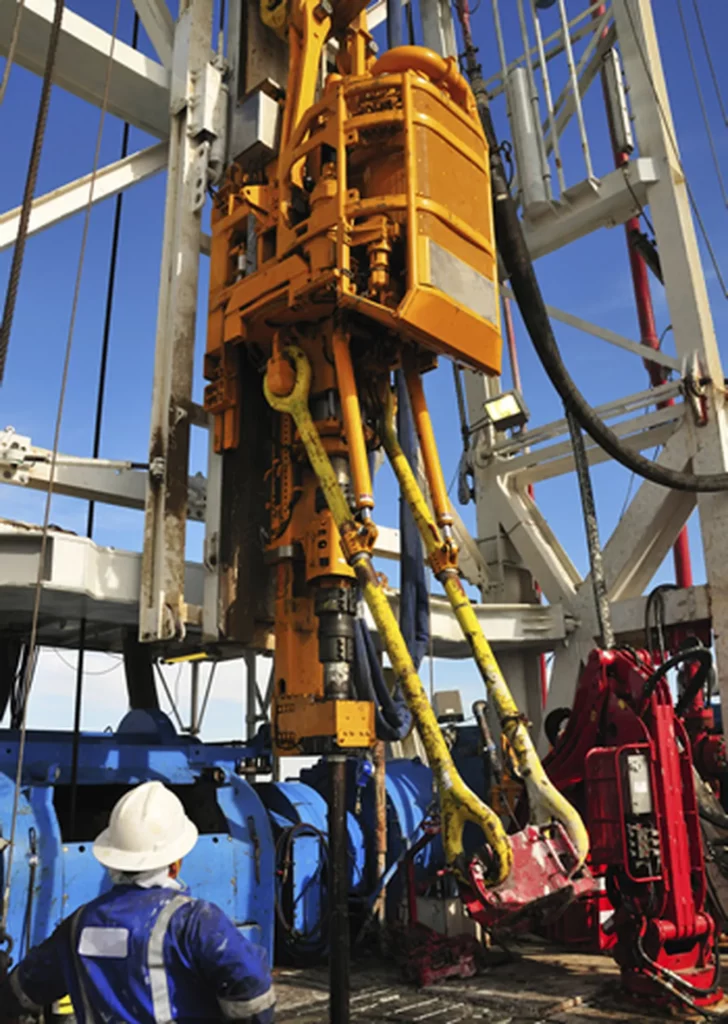

An oil/gas drilling platform derrick lifting cylinder is a hydraulic cylinder that is used to raise and lower the derrick on an oil or gas drilling rig. The derrick is a tall, four-legged structure that supports the drill string and other equipment used in drilling operations. The lifting cylinder is typically located at the base of the derrick and is attached to the derrick's substructure.

Derrick lifting cylinders are typically double-acting, meaning that they can both extend and retract. This allows them to raise and lower the derrick smoothly and efficiently. Derrick lifting cylinders are also typically very powerful, as they need to be able to lift the heavy derrick structure.

Derrick lifting cylinders are a critical component of oil and gas drilling rigs. They allow the derrick to be raised and lowered as needed, which is essential for drilling operations. Derrick lifting cylinders are also designed to be durable and reliable, as they operate in a harsh and demanding environment.

Here are some of the features and benefits of oil/gas drilling platform derrick lifting cylinders:

- High lifting capacity: Derrick lifting cylinders are designed to lift the heavy derrick structure, which can weigh hundreds of tons.

- Durability: Derrick lifting cylinders are made from high-strength materials and are designed to withstand the harsh and demanding environment of an oil or gas drilling rig.

- Reliability: Derrick lifting cylinders are critical components of oil and gas drilling rigs and are designed to operate reliably for long periods of time.

- Smooth operation: Derrick lifting cylinders are designed to raise and lower the derrick smoothly and efficiently, which is essential for safe and efficient drilling operations.

Oil/gas drilling platform derrick lifting cylinders are available in a variety of sizes and configurations to meet the specific needs of different drilling rigs.

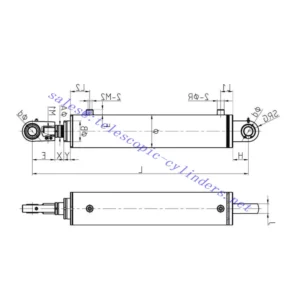

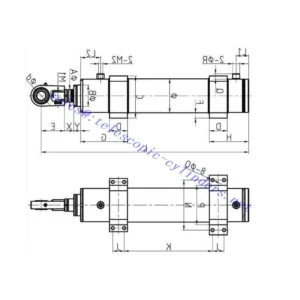

Oil/Gas Drilling Platform Derrick Lifting Cylinder Specifications:

| Product Name | Oil/Gas Drilling Platform Derrick Lifting Cylinder |

| Features: | Realize the lifting and lowering actions of the drilling platform. |

| Bore diameter: | 530mm |

| Rod diameter: | 490mm Stroke≤9000mm |

| Pressure: | Maximum 20.7MPa |

| Applications: | Oil/Gas Drilling Platform |

Oil/Gas Drilling Platform Derrick Lifting Cylinder Features:

The following are some of the advantages of using oil/gas drilling platform derrick lifting cylinders:

1. Reduced weight and center of gravity: Derrick lifting cylinders transfer vertical loads directly down to the drill floor, which reduces the overall weight and center of gravity of the derrick. This can improve stability and safety, especially in harsh offshore environments.

2. Increased lifting capacity: Derrick lifting cylinders can provide significantly more lifting capacity than traditional drawworks systems. This allows for the use of heavier and more complex drilling equipment, which can improve drilling efficiency and safety.

3. Reduced noise: Derrick lifting cylinders are much quieter than traditional drawworks systems. This can improve the working environment for rig workers and reduce noise pollution in the surrounding area.

4. Improved heave compensation: Derrick lifting cylinders can be used in conjunction with heave compensation systems to reduce the impact of wave motion on drilling operations. This can improve the accuracy and efficiency of drilling operations in offshore environments.

5. Reduced downtime: The redundancy of derrick lifting cylinders can help to reduce downtime in the event of a failure. For example, if one cylinder fails, the others can continue to operate at a reduced capacity until the failed cylinder can be repaired or replaced. This can help to minimize the financial impact of downtime on drilling operations.

6. Improved safety: The increased lifting capacity and reduced weight and center of gravity of derrick lifting cylinders can improve safety in a number of ways. For example, the increased lifting capacity allows for the use of heavier and more robust drilling equipment, which can help to reduce the risk of accidents. Additionally, the reduced weight and center of gravity can improve the stability of the derrick, which can also help to reduce the risk of accidents.

7. Increased efficiency: The increased lifting capacity and reduced noise of derrick lifting cylinders can help to improve the efficiency of drilling operations. For example, the increased lifting capacity allows for the use of heavier and more complex drilling equipment, which can improve the speed and accuracy of drilling. Additionally, the reduced noise can help to improve the communication and coordination between rig workers, which can also improve efficiency.

Oil/Gas Drilling Platform Derrick Lifting Cylinder Applications

Oil/gas drilling platform derrick lifting cylinders are used to raise and lower the derrick, which is a tower-like structure that supports the drilling equipment. Derrick lifting cylinders are typically large and powerful, as they need to be able to lift the weight of the derrick and all of the associated equipment.

Derrick lifting cylinders are used in a variety of applications on oil and gas drilling platforms, including:

Raising and lowering the derrick during rig move-in and move-out: When an oil rig is being moved to a new location, the derrick must be lowered to the ground. The derrick lifting cylinders are used to raise the derrick back into position when the rig arrives at its new location.

Raising and lowering the derrick during drilling operations: The derrick lifting cylinders are also used to raise and lower the derrick during drilling operations. This is done to allow the drill bit to be changed or to perform other maintenance tasks.

Raising and lowering the derrick during well completion operations: Once a well has been drilled, the derrick lifting cylinders are used to raise and lower the derrick during well completion operations. This includes installing the well casing and production tubing.

Derrick lifting cylinders are essential for the safe and efficient operation of oil and gas drilling platforms. They are designed to withstand the harsh offshore environment and the heavy loads that they must support.

In addition to the applications listed above, derrick lifting cylinders can also be used for a variety of other tasks on oil and gas drilling platforms, such as:

Raising and lowering the top drive

Raising and lowering the mud pump

Raising and lowering the drawworks

Raising and lowering the drilling line

Raising and lowering the casing running tool

Raising and lowering the cementing unit

Derrick lifting cylinders are a critical part of the oil and gas drilling process, and they play a vital role in the safe and efficient operation of oil and gas drilling platforms.

Hydraulic Cylinders for Oil/Gas Drilling Platform:

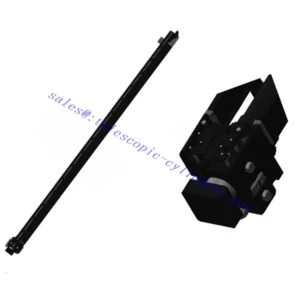

In order to explore and extract the oil and natural gas buried deep in the strata, people must use a variety of drilling equipment and tools to penetrate the hard and complex strata. Such high-intensity work and harsh environments are also a huge test for drilling equipment. Each hydraulic cylinder that we tailor-made for the equipment adopts highly professional computer management and simulation design to avoid possible problems in the application in advance and ensure better performance. Special coating treatment and strengthened sealing structure give hydraulic cylinders higher wear resistance, corrosion resistance, and durability. We can also provide a complete set of hydraulic systems, which not only ensure the power and accuracy required to complete the work but also fully meet the actual needs of customers.

In one of our projects, the customer chose our drilling derrick lifting system. The power unit composed of a diesel engine drive and constant pressure variable pump provides a continuous source of reliable power for the supporting lifting cylinder. The use of the main control valve can realize the independent or synchronous control of the two lifting hydraulic cylinders, and the control of the displacement is more accurate. Relying on the mastery of energy technology requirements, we can provide solutions to the various performance requirements of the equipment and also bring additional advantages to improve drilling equipment and its production.

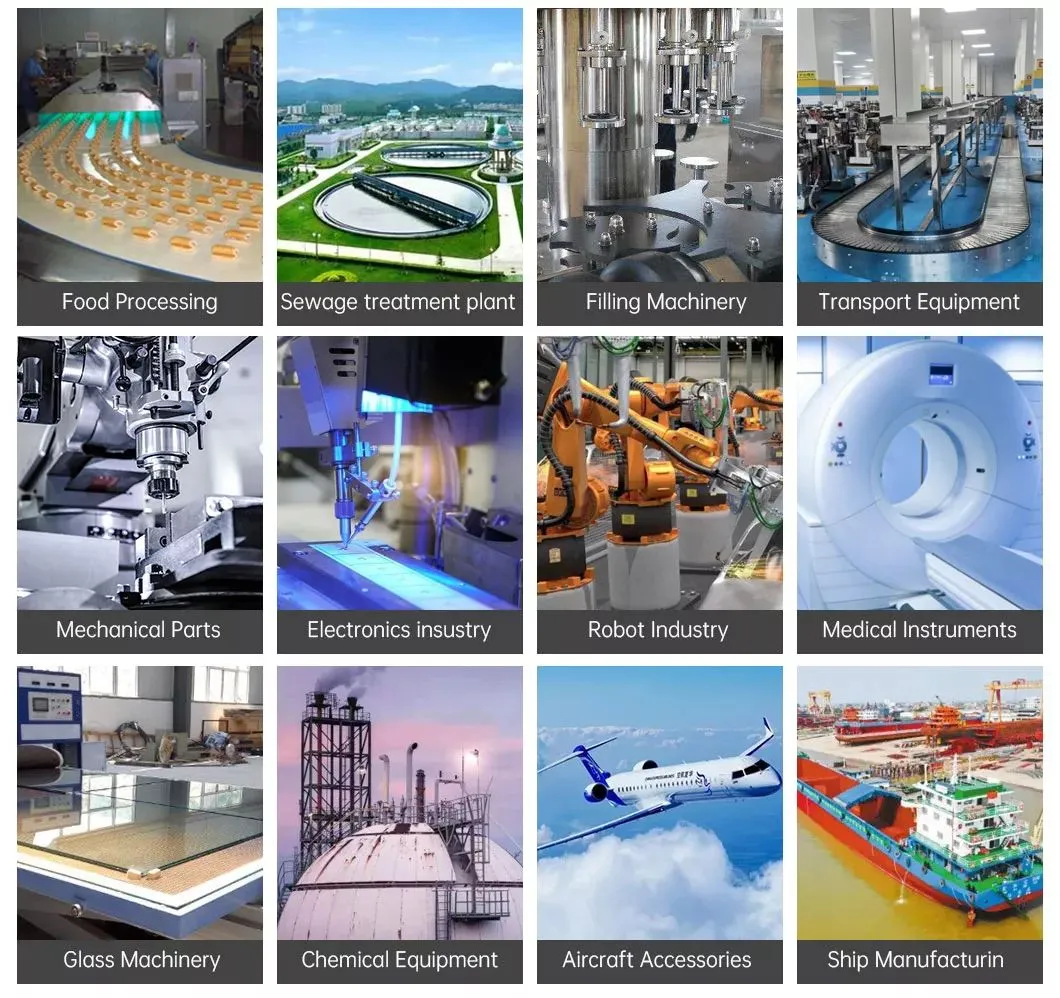

Moreover, we go beyond oil/gas drilling cylinders. We also supply a diverse range of hydraulic cylinders, including industrial vehicle hydraulic cylinders, aerial work vehicle cylinders, mobile machinery cylinders, industrial engineering cylinders, construction machinery cylinders, forklift hydraulic cylinders, agricultural machinery cylinders, crane hydraulic cylinders, sanitation machinery cylinders, excavator hydraulic cylinders, offshore hydraulic cylinders, energy technology cylinders, tunnel boring machine cylinders, and more. Our extensive product lineup caters to various industries and applications, providing solutions for your hydraulic needs.

We are one of the best telescopic cylinder manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair's adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair's base and connects to the seat or the chair's mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair's remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Application

Factory tour