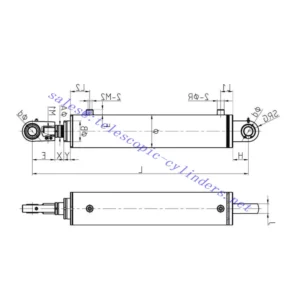

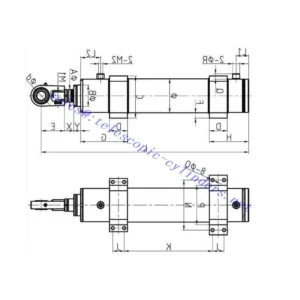

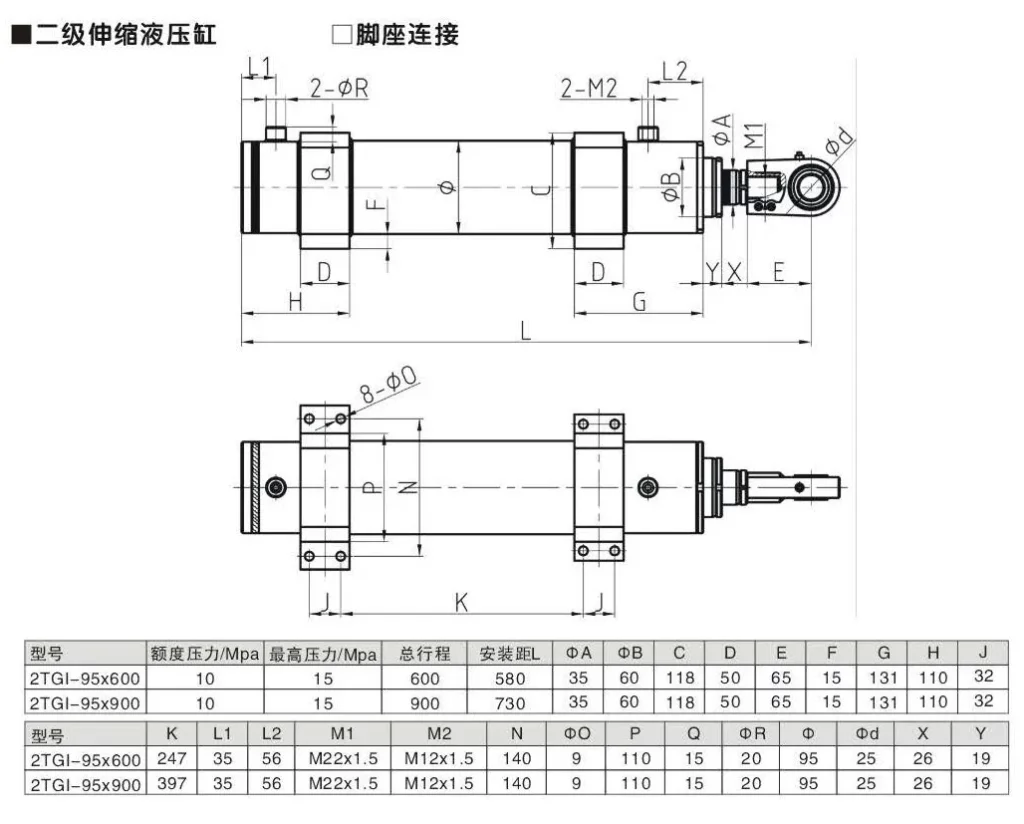

Foot Joint Two Stage Telescopic Hydraulic Cylinder

As one of the telescopic cylinder manufacturers, suppliers, and exporters of mechanical products, We offer telescopic cylinders and many other products.

Please get in touch with us for details.

Telescopic Cylinders

The foot joint two stage telescopic hydraulic cylinder is an advanced hydraulic component designed to deliver efficient and reliable power transmission in a wide range of industrial applications. With its innovative design, superior performance, and versatility, this hydraulic cylinder offers precise control and enhanced productivity. Whether used in construction, material handling, or agricultural machinery, the foot joint two stage telescopic hydraulic cylinder is engineered to optimize hydraulic operations and deliver exceptional results.

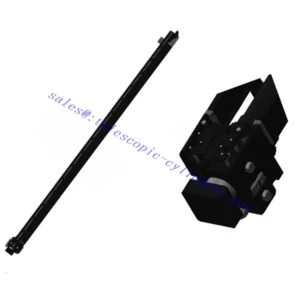

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical and horizontal machining center and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

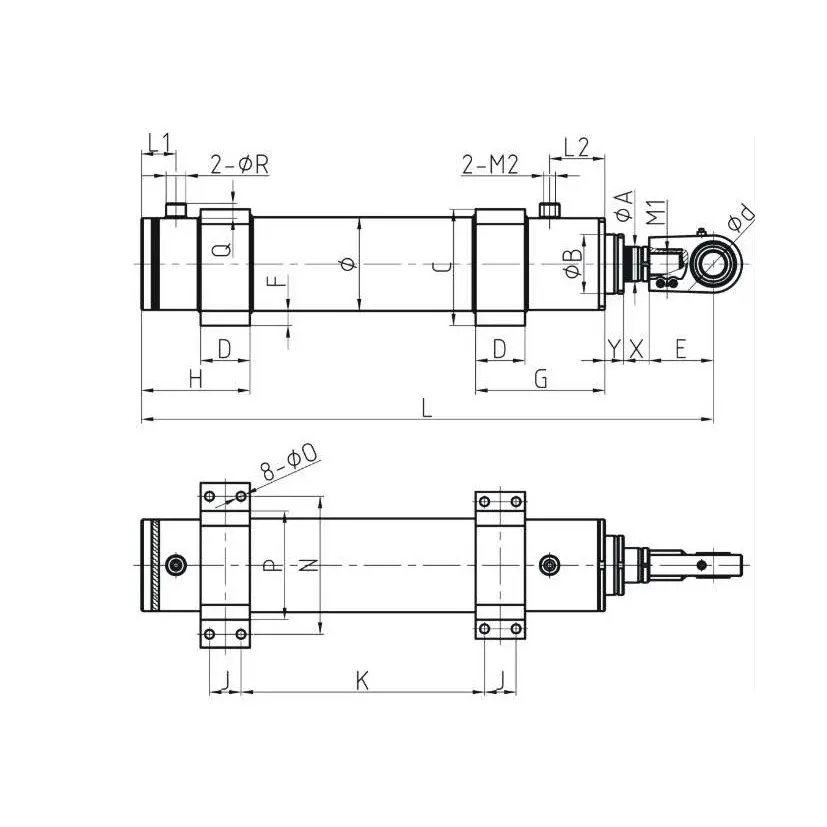

Foot Joint Two Stage Telescopic Hydraulic Cylinder Parameter:

Key Features and Benefits Of Foot Joint Two Stage Telescopic Hydraulic Cylinder:

- Two-Stage Telescopic Design:

- The Foot Joint Two Stage Telescopic Hydraulic Cylinder features a two-stage telescopic design that provides increased stroke length while maintaining a compact retracted size.

- This design allows for extended reach without compromising space constraints, making it ideal for applications where both reach and compactness are essential.

- Foot Joint Construction:

- The cylinder is equipped with a foot joint construction, which enables smooth and synchronized movement of the telescopic stages.

- The foot joint mechanism ensures stability, precise alignment, and excellent load-bearing capacity during operation.

- Precise Control:

- The Foot Joint Two Stage Telescopic Hydraulic Cylinder offers exceptional control over extension and retraction, allowing for precise positioning and efficient operations.

- The precise control mechanism ensures smooth and controlled movement, enhancing overall productivity and accuracy.

- High Load-Bearing Capacity:

- Engineered to handle heavy loads and demanding industrial applications, the Foot Joint Two Stage Telescopic Hydraulic Cylinder provides excellent load-bearing capacity.

- It is capable of lifting, pushing, or pulling substantial weights, making it a reliable choice for tasks that require significant force.

Usage Method Of Foot Joint Two Stage Telescopic Hydraulic Cylinder:

- Mounting and Installation:

- Identify the appropriate mounting position for the Foot Joint Two Stage Telescopic Hydraulic Cylinder based on your equipment or machinery requirements.

- Ensure that the mounting surface is sturdy, level, and capable of securely supporting the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using compatible hydraulic hoses or pipes.

- Align and secure the connections properly to prevent leaks and ensure optimal performance.

- Operating the Cylinder:

- Activate the hydraulic system to initiate the movement of the Foot Joint Two Stage Telescopic Hydraulic Cylinder.

- Utilize the hydraulic control system, such as valves or levers, to precisely control the extension and retraction of the cylinder for efficient operations.

China Hydraulic Cylinder Manufacturers:

HZPT is a company in the R&D and manufacture of compact hydraulic cylinders. It maintains a leading position in China's market segment of hydraulic cylinders. In 2020, the domestic market share was around 29%. We produce Industrial vehicle compact hydraulic cylinders, Aerial work vehicle compact hydraulic cylinders, agricultural machinery hydraulic cylinders, and sanitation machinery hydraulic cylinders.

We have a first-class independent R&D platform for assembly. The compact hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 essays. It has famous CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of critical equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

We are one of the best telescopic cylinder manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair's adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair's base and connects to the seat or the chair's mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair's remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Application

Factory tour