What Is A Telescopic Cylinders?

A telescopic cylinder, also known as a multi-stage cylinder or telescoping cylinder, is a type of hydraulic or pneumatic actuator that consists of multiple nested cylindrical stages or sleeves that extend and retract in a telescopic manner. Each stage is slightly smaller in diameter than the one before it, allowing them to fit inside one another.

The telescopic design of the cylinder allows for a longer stroke length while maintaining a relatively compact retracted length. This makes telescopic cylinders particularly useful in applications where a long stroke is required but space is limited, such as in dump trucks, cranes, aerial platforms, forklifts, and other lifting or extending mechanisms.

The operation of a telescopic cylinder is based on the principles of fluid power. In hydraulic systems, hydraulic fluid is used to transmit force and motion. When pressure is applied to the hydraulic fluid, it creates a force that pushes against the internal walls of the telescopic stages, causing them to extend. Conversely, when pressure is released or reversed, the fluid returns to the reservoir and the stages retract.

Telescopic Cylinders Advantage

Long Stroke Length

Telescopic cylinders provide a longer stroke length compared to their retracted length. This allows them to extend or retract over a greater distance, making them suitable for applications that require extended reach or extension capabilities.

Compact Design

One of the significant advantages of telescopic cylinders is their compact design when retracted. The nested stages allow for a reduced overall length, making them ideal for applications where space is limited or where a compact actuator is desired.

High Load Capacity

Telescopic cylinders have a high load-carrying capacity due to their multiple stages and robust construction. The load is distributed across the stages, which helps to evenly distribute the forces, providing increased stability and load-bearing capabilities.

Telescopic Cylinders For Sale

-

Aerial Work Platform Telescopic Cylinder

-

Double Shield Tunnel Boring Machine Support Shoe Cylinder

-

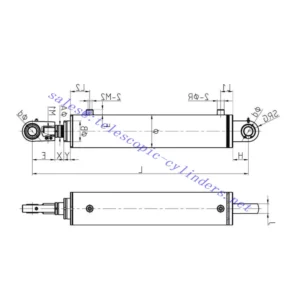

Earring Joint Two Stage Telescopic Hydraulic Cylinder

-

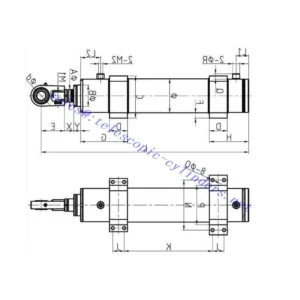

Foot Joint Two Stage Telescopic Hydraulic Cylinder

-

Mining Dump Truck Lifting Cylinder

-

Mobile Crane Telescopic Cylinder

-

Oil/Gas Drilling Platform Derrick Lifting Cylinder

-

Pin Joint Two Stage Telescopic Hydraulic Cylinder

-

Reach Stacker Telescopic Cylinder

How To Maintain Telescopic Cylinders?

Proper maintenance is crucial to ensure the optimal performance, longevity, and safety of telescopic cylinders. Here are some maintenance practices to consider for maintaining telescopic cylinders:

Regular Inspection: Perform regular visual inspections of the telescopic cylinder to check for any signs of wear, damage, or leaks.

Lubrication: Proper lubrication helps reduce friction and wear, ensuring smooth operation of the telescopic cylinder

Seal Replacement: The seals in telescopic cylinders are critical for preventing leaks and maintaining proper functioning

Cleanliness: Keep the telescopic cylinder and its surroundings clean to prevent the ingress of dirt, debris, or contaminants that can damage seals or hinder smooth operation

Avoid Overloading: Avoid exceeding the recommended load capacity of the telescopic cylinder

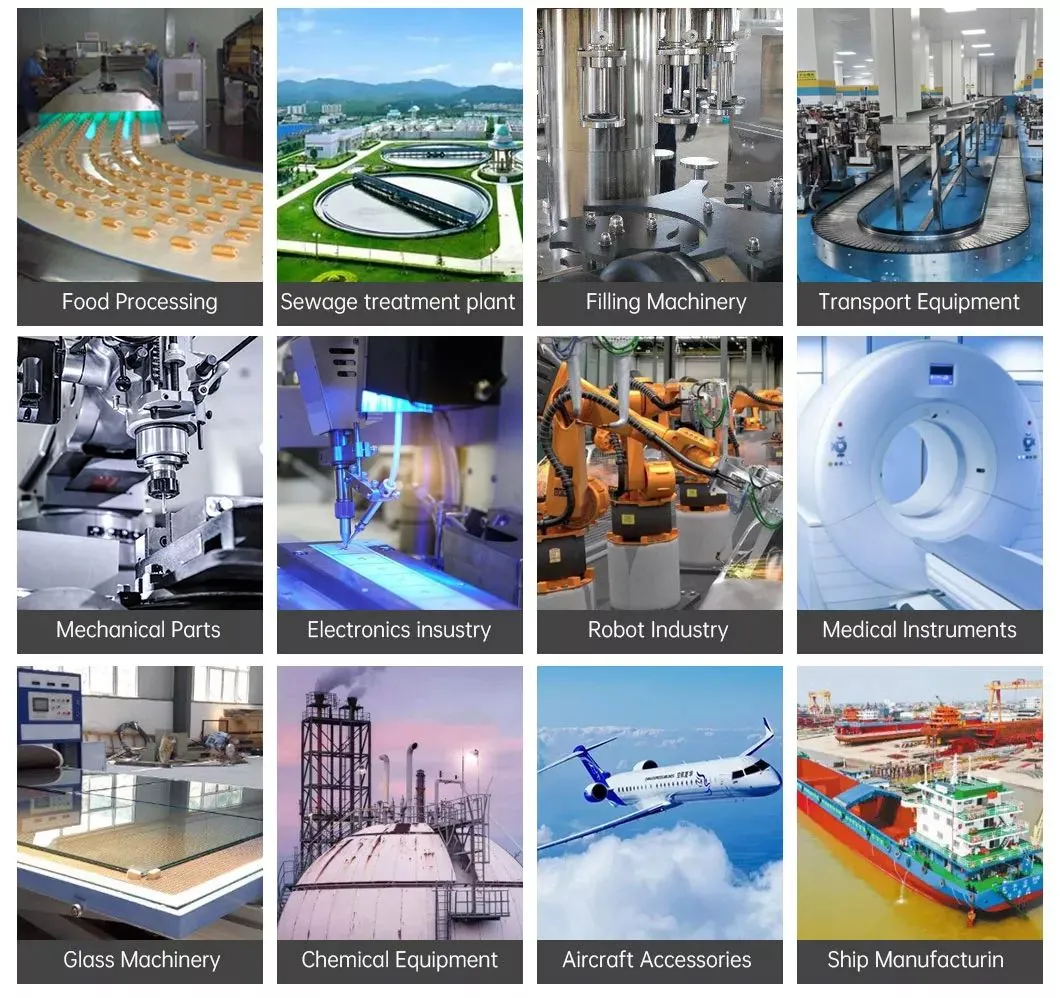

Application of Telescopic Cylinders

Dump Trucks and Trailers: Telescopic cylinders are extensively used in dump trucks and trailers for raising and lowering the dump bed. The long stroke length of the telescopic cylinder allows for efficient dumping of materials, such as gravel, sand, or construction debris.

Cranes and Aerial Platforms: Telescopic cylinders play a crucial role in cranes and aerial platforms to extend and retract the boom or lifting arm. The ability to achieve a long reach while maintaining a compact size makes telescopic cylinders ideal for these applications.

Material Handling Equipment: Telescopic cylinders are employed in various material handling equipment, such as forklifts and reach stackers, to extend and retract the lifting mast. This enables the lifting and positioning of loads at different heights while maintaining stability.

Mobile and Off-Road Equipment: Telescopic cylinders are used in mobile and off-road equipment, including agricultural machinery, construction equipment, and mining vehicles. They are utilized for extending and retracting booms, arms, buckets, or other attachments, providing versatile functionality.

Waste Management: Telescopic cylinders are employed in waste management applications, such as garbage trucks and compactors. They are used to compress and compact waste materials for efficient transportation and disposal.

Fire and Rescue Vehicles: Fire trucks and rescue vehicles often incorporate telescopic cylinders for extending and retracting ladder systems, elevating platforms, or aerial devices, enabling safe and efficient access to elevated areas.

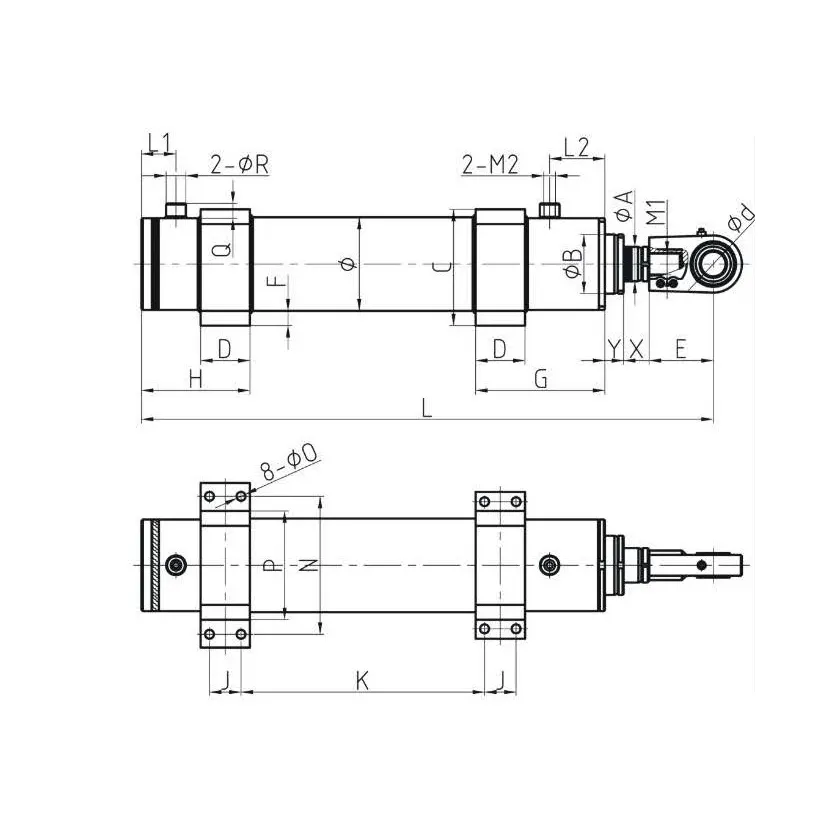

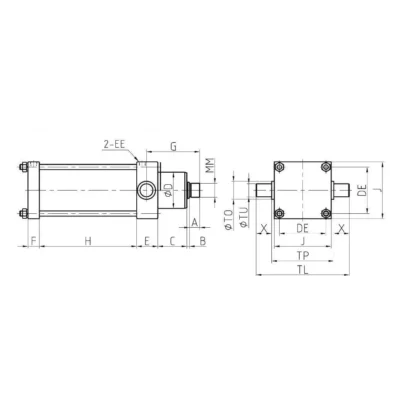

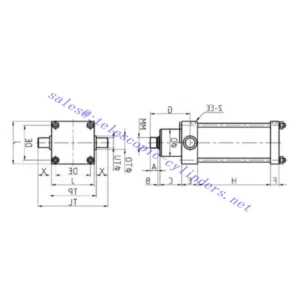

How To Measure Hydraulic Cylinder?

Bore Diameter:

Use a caliper or micrometer to measure the internal diameter of the cylinder bore. Ensure the measurement is taken at a few different points along the length to account for any potential variations.

Record the largest diameter measurement obtained.

Rod Diameter:

Measure the diameter of the rod using a caliper or micrometer. Take measurements at multiple points along the length to account for any tapering.

Record the smallest diameter measurement obtained.

Stroke Length:

Extend the cylinder to its maximum length and measure the distance from one end of the rod to the other. This measurement represents the stroke length.

Overall Length:

Measure from the base or mounting surface to the opposite end of the cylinder, accounting for any protruding components or fittings.